ZR-FZL-M digital pull-out adhesion tester

1、 Product Description

There are currently three main methods for testing the adhesion between coatings and substrates: one is the circle drawing method, one is the grid drawing method, and the other is the pull apart method. Both the circle drawing method and the grid drawing method can only classify adhesion ratings, but cannot quantify them specifically; The pull-out method can quantitatively (in Mpa) describe the specific size of adhesion, which is effective for comparing the adhesion size of different coatings and is very suitable for R&D personnel to use when developing formulas.

The ZR-FZL-M digital pull-out adhesion tester is an intelligent adhesion testing instrument developed by our company based on similar foreign products. It uses hydraulic pressure to perform pull-out testing on a specific area of coating, and the pull-out force can be accurately displayed on a digital display, with two different units of MPa and psi to choose from.

This instrument has the characteristics of simple operation, accurate data, low maintenance costs, and low prices of supporting consumables. The instrument has a USB interface, which is equivalent to a USB flash drive. After connecting to a computer through a data cable, the operator can directly export all test data.

This instrument is widely used for testing the adhesion between different coatings in some concrete base coatings, anti-corrosion coatings, or multi coating systems.

Experimental principle

The test sample or system is uniformly coated on a flat plate with a consistent surface structure.

After the coating system is dried/cured, the test column is directly bonded to the surface of the coating with a special adhesive.

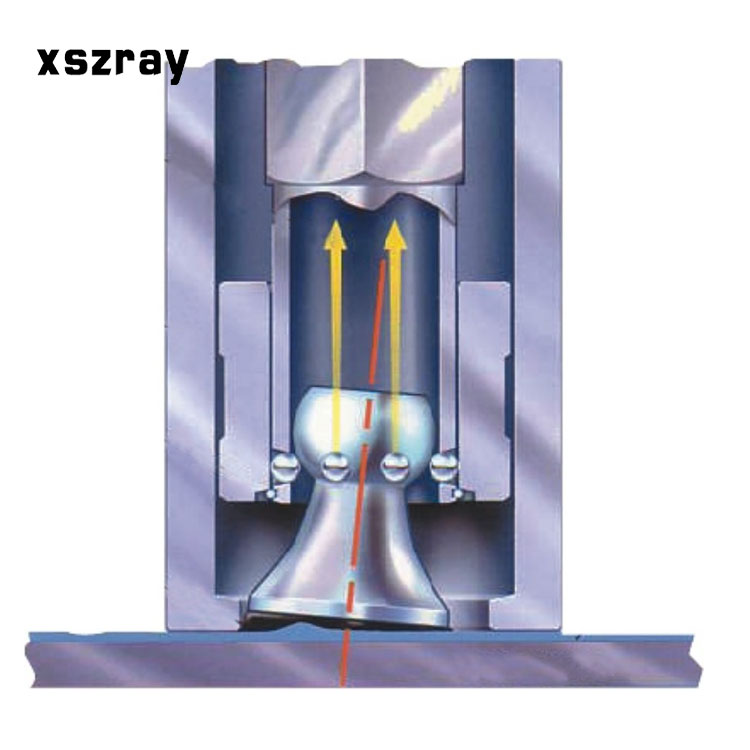

After the adhesive is cured, place the bonded test combination on the ZR-FZL-M digital pull-out adhesion tester. The tester uses a hydraulic pump to pull the test column evenly and at a speed not exceeding 1MPa/s from the coating. The required force is directly displayed on the instrument's LCD screen to test the force required to break the adhesion between the coating/substrate.

It is worth noting that using the tensile force between the failure interfaces (adhesion failure) or the tensile force of self failure (cohesion failure) to represent the test results, adhesion/cohesion failure may occur simultaneously.

2、 Main performance of the instrument

1. Portable design, built-in rechargeable lithium battery, no external power supply required, suitable for on-site and laboratory use;

2. Equipped with a Micro USB interface, the instrument functions like a USB flash drive when connected to a computer, allowing for direct copying of stored experimental data without the need for software installation, making it easy and convenient to use;

3. Complies with GB/T 5210, ASTM D4541/D7234, ISO 4624/16276-1 and other standards;

4. The machine is equipped with a real-time clock, and all saved data has corresponding experimental dates and times; Convenient for users to summarize and manage experimental data;

5. The pull-out spindle sizes provided for products with different adhesive strengths are 10, 14, 20, and 50mm, which expands the functionality and resolution of the instrument;

6. Each instrument is calibrated with NIST traceable pressure sensors before leaving the factory, with an accuracy of ± 1% of full scale,

7. Internally store pull-out data, including maximum pull-out force, pull-out rate, testing time, and the size of the pull-out spindle;

8. Pull off rate display, making it easier for operators to observe and adjust the pull off rate, in line with international standard testing methods;

9. Simply press the button to select the size of the pull-out unit, change the measurement unit, or store the reading;

10. No need to convert the table, the instrument automatically calculates the pull-out force according to the size of the pull-out unit;

11. The pull-out unit uses inexpensive and high-quality aluminum spindles that meet international standards, which do not require cleaning and can be used for long-term record keeping;

12. The aluminum automatic centering pull off unit ensures that the pull off force is evenly applied to the test results during smooth or uneven surface testing, preventing unilateral pull off;

13. Pressure sensors used in advanced industries ensure the continuity of accuracy;

14. LCD display, with two units: MPa or psi;

Compliant with standards

① ISO 4624 "Paintings and varnishes Pull off for adhesion"

② ASTM D 4541 "Standard Test Method for Pull Off Strength of Coatings Using Portable Adhesion Testers"

③ ASTM D7234 "Standard Test Method for Pull Off Adhesion Strength of Coatings on Concrete Using Portable Pull Off Adhesion Testers"

④ GB/T 5210 "Adhesion Test of Paint and Varnish by Pull off Method"

Main technical parameters

Spindle size: 20mm (standard); 10mm, 14mm, 50mm (optional)

Resolution: 0.01MPa (1psi)

Accuracy: ± 1% of full scale

Pull off strength: 10mm spindle → 0-80MPa; 14mm spindle → 0-40MPa; 20mm spindle → 0-20MPa; 50mm spindle → 0-3.5MPa;

Power supply: Built in rechargeable lithium battery and standard charging adapter power supply

Host size: 360mm × 75mm × 115mm (length x width x height)

Host weight: 3KG

Packaging information:

One main unit of the digital pull-out adhesion tester,

20mm aluminum test spindles (10 pieces),

One sleeve cutter,

A bottle of glue,

One Micro USB data cable,

One copy of the operating manual,

A lightweight and sturdy carrying case.