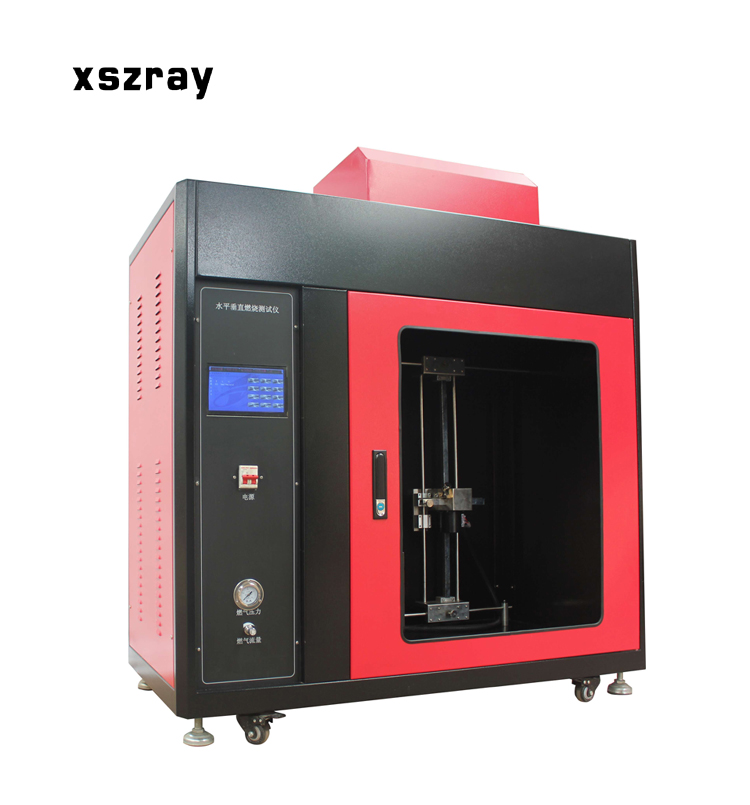

UL94 IEC60695-11 Horizontal and Vertical Flame Test Chamber

1、 Applicable scope

The horizontal and vertical combustion tester developed by Beijing Xinsheng Zhuorui Technology Co., Ltd. and Xunyu Technology Co., Ltd. is mainly used to test the combustion performance of plastic and non-metallic materials. The laboratory testing method for determining the horizontal or vertical combustion performance of plastic and non-metallic material specimens under 50W flame conditions.

2、 Product functional characteristics

1. Touch screen+PLC control;

2. High degree of automation: automatic recording of test time, automatic display of test results, automatic timing, automatic ignition, and automatic return of the Bunsen burner after flame application;

3. The front, back, up, and down movement of the style clamp can be controlled by touch screen. Start, stop, gas, timing, ignition, save, save, lighting, and exhaust are all controlled by touch screen. The test can be completed with a light touch of your fingertips; The horizontal and vertical combustion test programs can be switched on their own, and the test results are automatically stored and searchable;

4. Accurate timing, linear combustion rate V, automatic calculation, touch screen display for automatic saving.

3、 Related technical parameters

① Suitable working conditions and main technical indicators of the instrument

1. Environmental temperature: room temperature~40 ℃; Relative humidity: ≤ 75%;

2. Power supply voltage and power: 220V ± 10% 50HZ, power ≥ 150W;

3. Automatic ignition time of the Bunsen lamp: can be set arbitrarily;

4. The inner diameter of the Bunsen lamp is 9.5mm ± 0.5mm;

5. Gas source: liquefied petroleum gas (industrial methane gas added during arbitration);

6. Steel plate electrostatic spray box;

7. More than 0.5 cubic meters (for steel plate electrostatic spraying)

8. Instrument weight: approximately 100kg

9. Working power supply: 220V AC 50HZ

10. Timing range: 0~999.9s Timing accuracy: 10s ± 0.2s, 30s ± 0.2s;

11. Flame application time: 0-999.9S (adjustable, can be preset on the touch screen)

12. Residual flame time: 0-999.9S (adjustable)

13. Remaining burning time: 0-999.9S (adjustable)

14. Combustion angle: 0 °, 20 °, 45 ° optional

15. Flame height: 20mm ± 2mm-180mm ± 10mm adjustable

16. Flame temperature: (100-1000) ℃ adjustable

17. Gas flow rate: Gas flow rate 0ml/min-1000ml/min adjustable

18. Combustion lamp: inner diameter of lamp tube 9.5 ± 0.3mm, length: 100mm ± 10mm

19. Time device: can be precise to 0.1S

20. Position adjustment: the sample holder bracket can be adjusted up and down, left and right, the combustion seat can be adjusted back and forth, and the adjustment stroke is large

21. External dimensions: width 1160mm x depth 600mm x height 1310 (including feet) mm (0.5 square meters, with an additional 0.75 square meters)

22. Combustion test area volume: > 0.5 cubic meters, length * width * height about 900mm x 590mm x 1050mm, black background, background illumination ≤ 20Lux

23. Touch screen display screen related parameters:

① Size: 7 inches, effective display size: 15.4cm in length and 8.59cm in width;

② Resolution: 800 * 480

③ Communication interface RS232, 3.3V CMOS or TTL, serial port mode

④ Storage capacity: 1G

⑤ Using pure hardware FPGA driver display, with "zero" startup time, can run on power

⑥ Adopting M3+FPGA architecture, M3 is responsible for instruction parsing, FPGA-TFT display, good speed and reliability

⑦ The main controllers all use low-power processors and automatically enter energy-saving mode

24. Gas alarm device (optional)

25. Flame calibration device (optional)

a. Temperature testing range: 0-1000 ℃;

b. Flame temperature requirement: The time from 100 ℃± 2 ℃ to 700 ℃± 3 ℃ should be within 44s ± 2s;

C. c φ 0.5mm (K-type) nickel chromium/nickel aluminum wire thermocouple, insulated to ground;

d. Copper block: φ 5.5mm, with a mass of 1.76 ± 0.01g

② Design standards:

GB/T2408-2008 "Testing of Plastic Burning Performance - Horizontal and Vertical Methods" (ANSI/UL94-2006)

③ Applicable standards:

GB/T10707-2008 "Determination of Burning Performance of Rubber" Method B (i.e. GB/T13488 "Determination of Burning Performance of Rubber - Vertical Combustion Method")

Simulated safety test items specified in standards such as GB/T5169, ANSI/UL94, IEC60950-1, and IEC695-2-2.